Stock Code: 831045

Industrial Automation & Intelligence Solutions

Parameter:

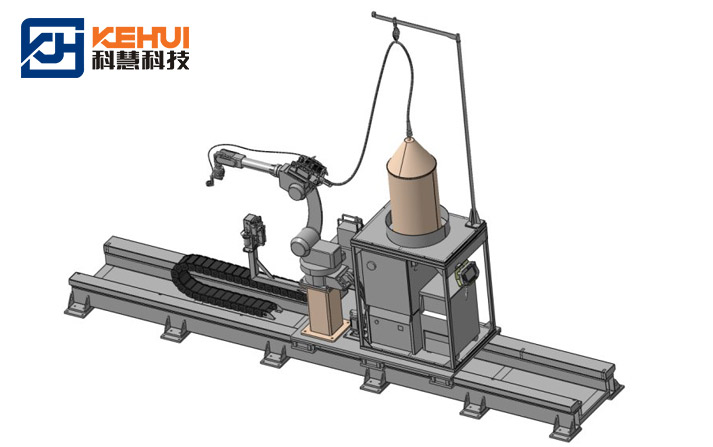

| Primary power supply | Three-phase AC 380±10% |

| Rated power | 50kVA |

| Secondary maximum short-circuit current | 15000A (under 5% load rate) |

| Electrode maximum pressure | 3000N |

| Welding clamp jaw depth | 350mm |

| Welding clamp electrode stroke | 120mm |

| Maximum weldable workpiece shape | 750*650mm |

| Working height | 850mm |

| Cooling water pressure | 0.20~0.30Mpa |

| Cooling water flow | 20~30L/min |

| Robot system (KUKA) | KR150-2 |

| Pneumatic system pressure (MPa) | 0.6 |

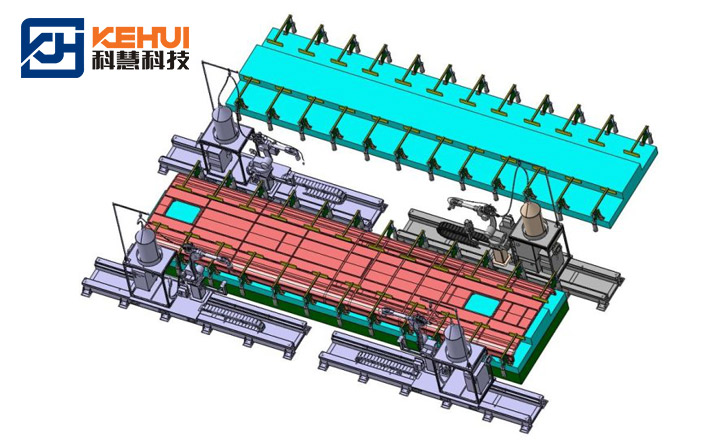

| System volume (length × width × height) | 6000×5000×2200 |

No Any Post.

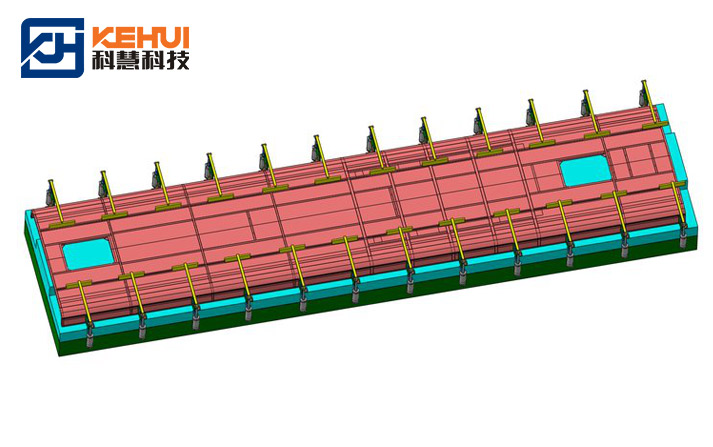

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.