Stock Code: 831045

Industrial Automation & Intelligence Solutions

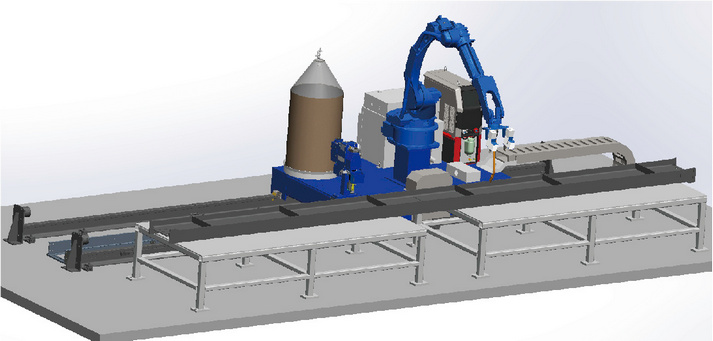

Main components and technical parameters:

1. DLP 3D Structured light sensor

DLP 3D cameras are more powerful than ordinary cameras. MEMS incorporates an imported blue light source, which is superior to traditional methods. MEMS infrared has stronger resistance to sunlight. Interference capability and finer detail Higher precision imaging effect

2. control system

such as a console, robot control system, communication system, and vision system, along with teaching-free software. The console adopts… The system utilizes centralized control and employs a programmable logic controller (PLC) for remote control and management of various devices. It features a user-friendly Chinese and English interface, making operation simple. The hardware configuration is as follows:

Monitor: 15 inches and above;

processor: I5-6500;

Memory: 8GB;

Hard drive: 512;

Communication interface: Ethernet ports *4, USB 3.0 Interface * 2;

3. PLC electrical system

The workstation can be started, stopped, paused, and activated via the start button. In case of an emergency… In case of emergency, the workstation can be stopped via the emergency stop button located anywhere on the main control panel, teach pendant, or start button station . It also provides audible and visual alarm prompts. The three-color operation indicator light flashes continuously after the system starts up, indicating the system ‘s standby status. Alarm, in operation, or in medium working condition.

The entire system adopts digital processing. It can connect to external devices via communication and provide on-site safety protection. The exterior is equipped with a touchscreen control panel to maximize safety in production. Sensors are configured between processes to detect action signals, ensuring… The equipment features interlocking mechanisms to ensure safety and reliability. It is also equipped with an emergency stop switch for immediate action in emergencies . Stop all operation of the equipment . In the event of an emergency stop due to a malfunction, the system will issue an alarm and the indicator lights on the control panel will illuminate. The palletizing robot workstation automatically stops. The equipment is equipped with a red… (Equipment alarm or malfunction), Yellow (Equipment paused) ,green (Equipment is running ) Three types of fault alarm indications and installed in a conspicuous location on the equipment. The operator can accurately know the current situation. System operating status.

The robot workstation electrical control and secondary development platform adopts a robot control cabinet. I/O for peripheral devices Control measures include the control of welding power source, wire feeding mechanism, material flow channel, positioner, compressed gas pressure, and shielding gas. Pressure detection, production line start/stop control, and other operations. The control cabinet contains relays, tri-color lights, buttons , buzzers, and lights. The electrical switches, push-button switches, pneumatic components, and connecting air pipes are all products from internationally renowned brands, and the control cabinet has excellent internal components. It has good sealing performance and ensures normal operation within the range of -15℃ to +45℃.

The information is transmitted to the customer’s central control system.

4. Process Database

Welding process parameters can be manually selected through an interactive interface maintained by a process database; the software system also provides operators with… The interactive interface for manually configuring welding parameters allows users to configure a new set of process parameters, which are then processed by the motion control subsystem. Through simulated and actual welding tests, process parameters were continuously adjusted until suitable welding process parameters were obtained. Click on the [link/method] on this interface. Add a button to save the process parameter to the process database.

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.