When companies start evaluating automation partners, many assume all robotic systems integration providers are essentially the same. A robot is a robot, right? Not quite.

The difference between integrating a robotic arm for welding and deploying an automated palletizing robot is not subtle—it’s structural, electrical, mechanical, and deeply process-driven. Choosing the wrong integrator can mean years of unstable production.

This article breaks down what truly separates welding-focused integrators from palletizing-focused ones—and why that distinction matters.

1️⃣ Process Complexity: Arc Physics vs. Motion Logistics

At first glance, both welding and palletizing use six-axis robots. But the similarity ends there.

A robotic arm for welding must control arc length, heat input, weaving amplitude, torch angle, and wire feed stability—all simultaneously. In a robotic arm welding machine, millisecond-level arc fluctuation affects bead penetration and structural integrity.

By contrast, an automated palletizing robot primarily manages position repeatability and payload control. While accuracy matters, it doesn’t need to compensate for molten metal dynamics, thermal distortion, or weld pool behavior.

In short:

-

Palletizing = motion coordination

-

Welding = motion + energy + metallurgy + real-time correction

This is why serious robotic systems integration for welding demands far deeper process engineering.

2️⃣ Tooling & End Effector Demands

An automated palletizing system typically uses vacuum grippers or mechanical clamps. Once tuned, the tool rarely changes.

A robotic arm for welding, however, is part of a living thermal system:

-

Welding power source matching

-

Torch cooling systems

-

Wire feeder synchronization

-

Anti-collision devices

-

Fume extraction integration

In a robotic arm welding machine, improper torch cable routing alone can cause arc instability. These are issues palletizing integrators rarely encounter.

This is why many general industrial robotic solutions providers perform well in packaging lines—but struggle in structural welding cells.

3️⃣ Accuracy vs. Adaptive Compensation

Palletizing integrators optimize for cycle time and stacking patterns. An automated palletizing robot follows predefined coordinates, and adjustments are minimal once layout stabilizes.

Welding is different.

Even the best fixtures experience:

-

Part tolerances

-

Heat distortion

-

Gap variation

A robotic arm for welding often requires seam tracking, arc voltage control, or laser guidance. Without adaptive programming, a robotic arm welding machine becomes just an expensive positioning tool.

True welding-focused robotic systems integration accounts for real-world part variation—not just CAD perfection.

4️⃣ Fixture Engineering: The Hidden Divider

In palletizing, fixtures are simple: pallets, conveyors, separators.

In welding, fixtures define success.

An experienced welding integrator designs:

-

Heat-resistant clamping systems

-

Distortion control structures

-

Multi-station rotating positioners

-

Stress-release strategies

A robotic arm for welding is only as stable as the fixture holding the workpiece. Many palletizing-focused industrial robotic solutions providers underestimate this.

And when distortion appears, they blame the robot.

5️⃣ Programming Depth

Programming an automated palletizing system revolves around path logic and stacking rules.

Programming a robotic arm welding machine involves:

-

Multi-layer weld sequences

-

Interpass temperature control

-

Travel speed optimization

-

Weaving parameter calibration

-

Start/stop crater treatment

The programming philosophy is entirely different.

Strong robotic systems integration in welding requires welding engineers—not just robot programmers.

6️⃣ Risk Profile & Failure Impact

If a pallet is misstacked, the result is operational inefficiency.

If a weld fails, the result can be:

-

Structural collapse

-

Product recalls

-

Safety hazards

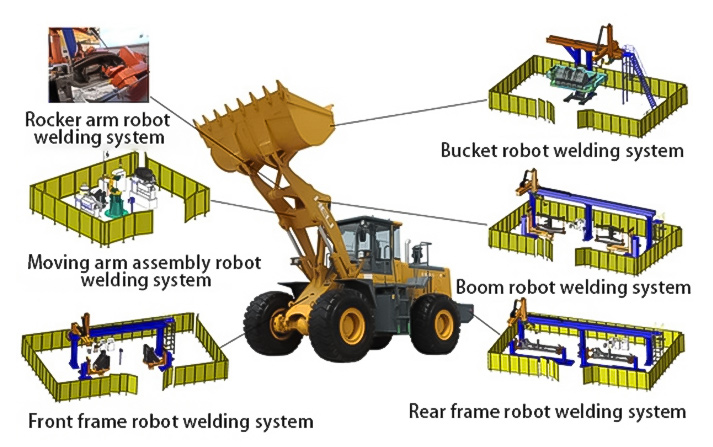

A robotic arm for welding often serves industries like construction machinery, pressure vessels, or heavy steel structures. Risk tolerance is near zero.

This is why welding-focused industrial robotic solutions providers must understand certification standards, weld inspection methods, and process validation.

An automated palletizing robot integrator may not operate under such strict quality frameworks.

7️⃣ Long-Term Scalability

Both palletizing and welding systems can scale—but differently.

An automated palletizing system scales by increasing throughput or adding additional robots.

A robotic arm welding machine scales by:

-

Expanding product types

-

Adding multi-robot synchronization

-

Integrating positioners and rails

-

Upgrading power sources for thicker materials

Scaling welding automation requires long-term process planning, not just layout expansion.

That’s where specialized robotic systems integration matters most.

Why Specialization Matters in Welding Automation

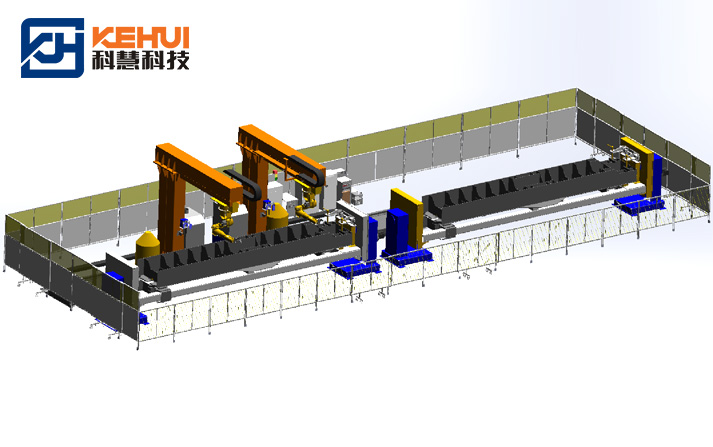

Since 1994, our focus has not been generic automation—it has been welding-centric robotic systems integration.

We design and deliver:

-

Structural steel welding cells

-

Heavy fabrication welding lines

-

Multi-station robotic arm welding machine systems

-

Fully integrated industrial robotic solutions for manufacturing plants

Our engineers understand not only the robotic arm for welding, but also:

-

Arc behavior under varying voltage loads

-

Fixture stress management

-

Production takt-time balancing

-

On-site commissioning in real factory environments

We export globally and deploy engineers directly to customer sites for installation guidance and parameter tuning. Because welding automation cannot be finalized remotely—it must be tuned under real arc conditions.

Unlike integrators that move between palletizing and welding without depth, our expertise is built around welding process stability and structural reliability.

If your project demands more than just an automated palletizing robot, and you require true welding-driven robotic systems integration, then specialization is not optional—it is essential.

And that is where we stand.